Plastic extruder

VFD applied in plastic extruder

1, Load feature

There is a screw rotates in the tube body to push the plastic material move ahead, the screw typewill increase the pressure to overcome the big resistance.

Plastic extruder is constant torque load, it needs high output torque, and meantime the

temperature on the site is always high and dust will be more.

.

2, Requests for frequency inverters (VFD)

(1) Control is simple.

(2) Output high torque at low frequency..

(3) Heat sink performance of frequency inverter must be good.

.

3, Instruction for commissioning

(1) Pictures of plastice extruder

(2) Parameters setting list

No. | Function codes | Default | Setting value | Explanation |

1 | F00.00 | 2 | 2 | V/f control |

2 | F00.01 | 0 | 1 | External start / stop signal |

3 | F00.06 | 10 | 2 | External VI signal (analog signal) to control the output frequency |

4 | F00.12 | Model depend | Power * 2 | Set the acceleration time based on real request |

5 | F00.13 | Model depend | Power * 2 | Set the deceleration time based on real request |

6 | F07.02 | 3 | 3 | Fault output |

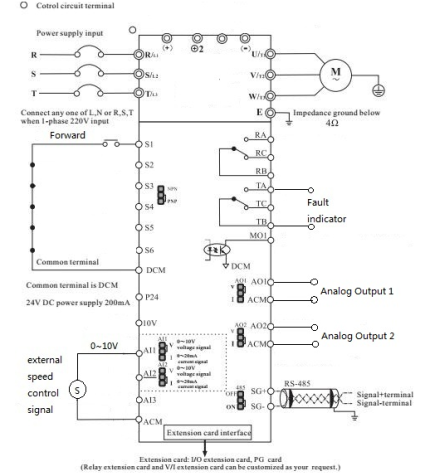

(3) Typical wiring diagram

4, Notices

(1) During commissioning, the motor running direction must be checked correctly.

(2) Before starting the motor, the system temperature must be ready, if the temperature is notready, the material inside the tube body will be blocked, it will cause high start current, thefailure of overload will happen.

(3) Maintenance regularly, pay attention to dust prevention and heat sink for frequency inverter.