Plastic film blowing machine

VSD applied in platic film blowing machine

1, Load feature

There are two parts on plastic film blowing machine can get energy saving:

(1) Power driven system, most of this part will install an additional frequency inverter, which make the main motor works at 30~40Hz to get energy saving;

. (2) Heating system, most of this part will install an electromagnetic heater to get energy saving.

2, Requests for frequency inverters (VSD)

(1) Output high torque at low frequency.

(2) High speed control accuracy. (to avoid the raised grain occurs on the film).

3, Instruction for commissioning

(1) Pictures of plastic film blowing machine

(2) Parameters setting list (take 15Kw, 5.5kW motor as example)

|

No. |

Function codes |

Default |

Setting value |

Explanation |

||

|

1 |

F00.01 |

0 |

1 |

Start / stop by external signal |

15kW main motor |

|

|

2 |

F00.06 |

10 |

10 |

The motor speed is adjusted by keypad potentiometer. |

||

|

3 |

F00.12 |

Model depend |

15s |

Acceleration time (adjustable) |

||

|

4 |

F00.13 |

Model depend |

15s |

Deceleration time (adjustable) |

||

|

5 |

F04.01 |

0.0 |

2.0 |

Torque boost (adjustable) |

||

|

|

||||||

|

1 |

F00.01 |

0 |

1 |

Start / stop by external signal |

5.5kW motor |

|

|

2 |

F00.06 |

10 |

10 |

The motor speed is adjusted by keypad potentiometer. |

||

|

3 |

F00.12 |

Model depend |

15s |

Acceleration time (adjustable) |

||

|

4 |

F00.13 |

Model depend |

15s |

Deceleration time (adjustable) |

||

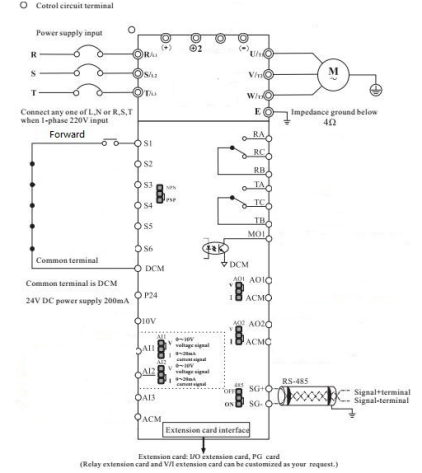

(3) Typical wiring diagram

4, Notices

The temperature is always high on the site, pay attention to dust prevention and heat sink for frequency inverter.