variable freqyency drive applied in CNC machine

variable freqyency drive applied in CNC machine

1, Load feature

CNC machine is a mechanical-electrical integrated system include mechanic, electric, hydraulic, pneumatic, microelectronics and information technology, it has the features of high accuracy, highly automated and highly flexible.

2, Requests for inverters (VFD)

(1) It can work normally at 300RPM speed, has good stability, high control accuracy, fast response speed and high output torque at low speed.

(2) It should have external forward / reverse control signal and analog input signal.

3, Instruction for commissioning

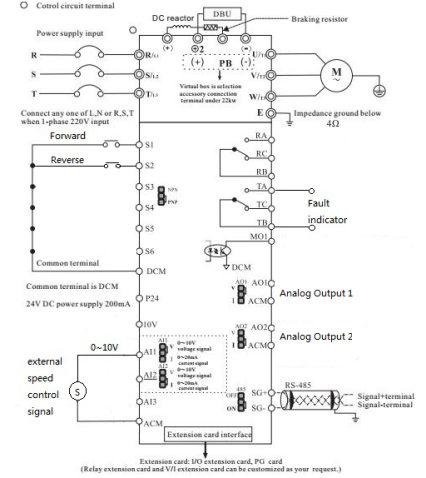

(1) System diagram

(2) Parameters list (Take 380V, 4KW as example)

|

No. |

Function codes |

Default |

Setting value |

Explanation |

|

1 |

F00.00 |

2 |

0 |

Sensorless vector control (SVC) |

|

2 |

F02.01 |

Model depend |

- |

Set them based on the motor nameplate value |

|

3 |

F02.02 |

Model depend |

- |

|

|

4 |

F02.03 |

Model depend |

- |

|

|

5 |

F02.04 |

Model depend |

- |

|

|

6 |

F02.05 |

Model depend |

- |

|

|

7 |

F02.37 |

0 |

2 |

Rotation autotuning (disconnect the load) |

|

8 |

F00.01 |

0 |

1 |

External start / stop signal |

|

9 |

F00.06 |

10 |

2 |

External VI signal (analog signal) to control the output frequency |

|

10 |

F00.03 |

50Hz |

100Hz |

Set the max. frequency based on real request |

|

11 |

F00.04 |

50Hz |

100Hz |

Set the upper limit frequency based on real request |

|

12 |

F00.12 |

Model depend |

0.5s |

Set the acceleration time based on real request |

|

13 |

F00.13 |

Model depend |

0.5s |

Set the deceleration time based on real request |

|

14 |

F01.09 |

0 |

0.5 |

DC braking start frequency while stopping |

|

15 |

F01.10 |

0 |

0s |

DC braking delay time while stopping |

|

16 |

F01.11 |

0% |

100% |

DC braking current while stopping |

|

17 |

F01.12 |

0s |

1s |

DC braking time while stopping |

(3) Typical wiring diagram

4, Notices

(1) Under the SVC control mode, it must perform the auto tunning firstly, then set the other parameters.

(2) Please pay attention to ACC/DEC time setting and also the braking resistor’s selection.

(3) The installation environment should be safe, to avoid the iron dust and other items to enter into inverter.