VT200 Series Mini Type AC Drive are developed for general applications of small power and OEM market. It applies SVC and V/F control technology, making the functions of PID, multiple-speed step, DC braking(optional), Modbus communication, as well as less installation space .VT200 Series AC drive is for small automation equipment of economical type, especially suitable for electronic equipment, food packaging, wood, glass and other small power transmission.

Main Features

1.Output frequency :0-3200Hz.

2.Fire mode

3.Remote control operation keypad, convenient for remote control.

4.Sensorless Vector Control 180% torque at 0.5Hz

5.Overload:150% for 1 minute and 180% for 10 seconds

6.Build-in simple PLC function、textile swing frequency function、fix length control Module

7.Auto current limiting and voltage limiting and under-voltage restrain .

8.Output automatic voltage regulation function(AVR)

9.Built-in PID regulation function to facilitate the realization of closed loop control of the temperature ,pressure and flow . and reduce the cost of the control system .

10.MODBUS communication protocol .

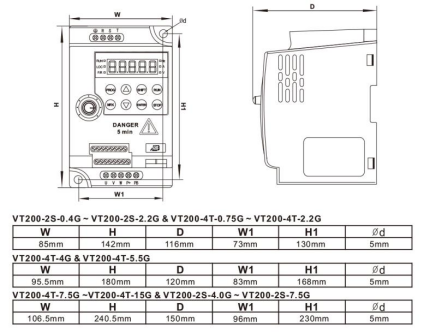

Product Outline Drawing

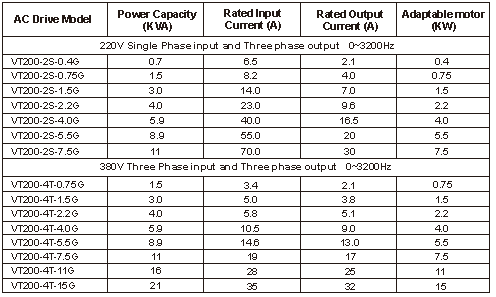

VT200 Model List

Technical Specification

|

Electrical |

Input voltage |

single/three phase 200-240V,three phase 380-440V |

|

fluctuation±10%,imbalance<3% |

||

|

Input frequency |

50/60Hz ± 5% |

|

|

Output voltage |

0V-input voltage |

|

|

Output frequency |

0-3200Hz |

|

|

Performance |

Overload capacity |

60s for 150% of the rated current, 10s for 180% of the rated current |

|

Frequency Control mode |

Sensorless vector control (SVC) |

|

|

Command control mode |

Operation panel control,Terminal control,Communication control |

|

|

Speed control mode |

Digital setting、Analog setting、Communication setting |

|

|

Speed control resolutions |

Digital setting: 0.01 Hz Analog setting: maximum frequency x 1% |

|

|

Speed stability accuracy |

SVC:±0.5% |

|

|

Speed adjustment range |

SVC:1:100 |

|

|

Torque response time |

SVC:<200ms |

|

|

Startup torque |

SVC:0.5Hz:180% |

|

|

Torque control accuracy |

±5% |

|

|

Motor parameter learning ability |

When high torque is required on site, first input parameters such as motor power and current in group P1. Dynamic or static motor parameters can be set in p1-37. After self-learning, the motor output torque and response ability will be stronger. |

|

|

Speed tracking restart |

This machine has the motor speed tracking ability of simple software detection mode. when used, it is recommended to input the motor rated power and rated current parameters first. |

|

|

Individualized |

Programmable I / O terminal |

input & output terminal function can be edited |

|

Process PID regulation function |

Built in process PID module |

|

|

Simple PLC function |

Built in simple PLC module, which can realize timing and multi-stage frequency output |

|

|

Textile swing frequency function |

Build-in textile swing frequency function modular |

|

|

Fixed length control function |

Build-in fixed length control modular |

|

|

Communication protocol |

MODBUS |

|

|

Protection |

Over-voltage lost speed control |

Bus voltage is automatically controlled to prevent overvoltage fault caused by deceleration power generation of large inertia load |

|

Automatic current limiting protection |

The output current is automatically limited to prevent heavy load overcurrent fault, and the heavy load has the performance of over-current speed limit of excavator |

|

|

Input and output phase loss protection |

Automatic detection and alarm function of output phase loss |

|

|

Process PID setting and feedback loss detection |

Process PID automatically identifies whether the given and feedback are lost, and the loss alarm function |

|

|

Output short circuit protection |

Effective protection function of output short circuit to ground |

|

|

Output phase to phase short circuit protection |

Effective protection function of output phase to phase short circuit |

|

|

Module overheating protection |

When the load is too heavy, fan damaged or cooling air duct blocked, Real time monitor the module temperature for hot spot protection |

|

|

Fan start-up temperature control |

The fan only rotates when the frequency converter is running. When the temperature is high, the fan will delay shutdown |

|

|

I/O features |

External analog power supply |

+10V,Load capacity 100mA, which is used for external analog power supply with short-circuit protection |

|

External digital power supply |

+24V, Load capacity 200mA |

|

|

Analog input |

AI1:Voltage 0-10V and Current 0-20mA can be set and select input way by the software menu |

|

|

Analog output |

AOV:0-10V、AOI:0-20mA, 4~20mA can be output through parameter setting |

|

|

Digital input |

DI1-DI5,DI5 can be high speed pulse,0~50KHZ |

|

|

Digital output |

FM digital output,high-speed pulse output,0~50KHZ |

|

|

Relay output |

TA/TB/TC:contact capacity 250VAC/3A or 30VDC/1A(On-off timing relay setting function) |

|

|

MODBUS-RTU Communication |

A+、B- terminal match international standard MODBUS-RTU protocol format |

|

|

Extended keyboard (optional) |

RJ45 terminal can connecte with an external keyboard, and can adjust speed or monitor or control parameters with external keyboard |

|

|

Operation |

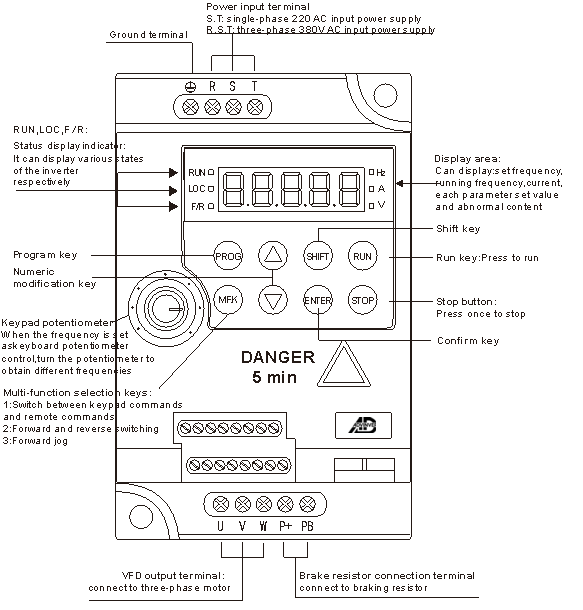

LED display |

5 digit LED |

|

Setup frequency/output frequency/output voltage/output current/motor speed/output torque/Switching value terminal/status parameter/programming menu parameter and fault code, etc |

||

|

Indicator |

3 unit indicators, 3 status indicators |

|

|

Environment |

Ambient temperature |

*-10℃~+40℃,Maximum temperature 50℃,The change of air temperature is less than 0.5 ℃ / min |

|

Derated for use at 40-50 ℃: derated the output current by 2% each exceeds 1 ℃ |

||

|

Storage temperature |

*-40℃~+70℃ |

|

|

Installation environment |

Indoor, prevent from direct sunlight, dust, corrosive gas, combustible gas, oil mist, water vapor, water or salt, etc |

|

|

Altitude |

Below 1000 m (de-rated 1% for each 100 m higher),Maximum 3000m |

|

|

Humidity |

Maximum relative humidity 95%, non-condensing |

|

|

Vibration |

3.5m/s2 at 2Hz~9Hz, 10m/s2 at 9Hz~200Hz(IEC60721-3-3) |

|

|

IP level |

IP20 |

|

|

Pollution level |

Class 2 (dry, non-conductive dust pollution) |

Main Circuit Connection