VT200P series is a high performance general purpose AC drives integrated with the most advanced open & closed-loop vector control with PG. It can drive both normal AC asynchronous induction motors and PM synthronous motors with excellent control performance. Furthermore, it is designed to be robust with large capacity for heavy duty and complicated motor driving applications.

Main features:

- 1.Output frequency 0~500Hz

- 2.Feedback Vector Control Torque 180% at 0Hz

- 3.Dual rating design: 120% for 60 seconds for Normal Duty;

- 150% for 60 seconds for Heavy Duty

- 4.Auto voltage regulations(AVR) keep constant output voltage automatically when the main voltage change

- 5.Multiple protect functions: Motor short-circuit detection at power-on, power input/output phase loss protection, overcurrent protection, overvoltage protection, undervoltage protection, overheat protection and overload protection

- 6.Non-stop at momentary power failure

- 7.LCD panel and parameter replication

- 8.KEY locking and function selection

- 9.Fire mode

- 10.Built-in RS-485(Modbus) and various communication card options: CANopen, Profibus DP, CANlink

Technical Specification

|

Basic specifications |

Output frequency |

SVC: 0~500HZ FVC:0~500Hz V/F:0~500Hz |

|

Carrier frequency |

0.5kHz~16kHz, adjusted automatically based on the load features |

|

|

Input frequency resolution |

Digital setting:0.01Hz Analog setting:maximum frequency x 0.025% |

|

|

Input frequency accuracy |

Digital setting: maximum frequency x ±0.01% Analog setting: maximum frequency x ±0.01% |

|

|

Control mode |

Sensorless vector control(SVC), Feedback vector control(FVC) V/F control |

|

|

Startup torque |

G: 0.5Hz/150%(SVC) | 0Hz/180%(FVC) P:0.5Hz/100% |

|

|

Speed adjustment range |

1:100(SVC) 1:1000(FVC) |

|

|

Speed stability accuracy |

±0.5%(SVC) ±0.02%(FVC) |

|

|

Torquecontrol accuracy |

±5%(FVC) |

|

|

Overload capacity |

G: 60s for 150% of the rated current | 3s for 180% of the rated current P: 60s for 120% of the rated current | 3s for 150% of the rated current |

|

|

Torque boost |

Auto torque boost; Manual torque boost 0.1%~30% |

|

|

Motor auto-tuning |

With-load auto-tuning; no-load auto-tuning |

|

|

V/F Curve |

Liner V/F, multi-point V/F, Square V/F (1.2-power V/F, 1.4-power V/F, 1.6-power V/F,1.8-power V/F, 2-power V/F) |

|

|

V/F separation |

Complete separation,V/F half separation |

|

|

Acceleration/ Deceleration curve |

Linear or S-curve acceleration/deceleration 4 type acceleration/deceleration time, range 0.0~6500.0s |

|

|

DC braking |

DC braking frequency: 0.00Hz~Maximum frequency Brake time: 0.0s~36.0S Braking action current value: 0.0%~100.0% |

|

|

Jog control |

Jog frequency range: 0.00Hz~50.00Hz Jog acceleration/deceleration time: 0.0s~6500.0s |

|

|

Simple PLC |

To achieve time and multi-frequency output with internal simple PLC module |

|

|

Multi-speed |

A maximum of 16 speeds supported |

|

|

Build-in PID |

Easily realized process control closed-loop control system |

|

|

Auto voltage regulation (AVR) |

Keep constant output voltage automatically when the mains voltage changes |

|

|

Protection functions |

Motor short-circuit detection at power-on, power input/output phase loss protection, overcurrent protection, overvoltage protection, undervoltage protection, overheat protection and overload protection

|

|

|

|

|

|

|

Individualized functions |

Non-stop at momentary power failure |

This function enables the AC drive to compensate the DC bus voltage reduction with the load feedback energy by reducing the output frequency so as to keep the AC drive running continuously |

|

Virtual I/O |

5 group virtual I/O, implement simple logic control |

|

|

Compatible with a variety of communication protocols |

Support 4 type Modbus: Modbus, Profibus-DP, CANlink,CANopen |

|

|

Switch over among multi motor |

switch over the running among two motors

|

|

|

Multiple Encoder type |

ABZ incremental encoder, UVW incremental encoder,Resolver,SIN/COS encoder,wire-saving UVW encoder |

|

|

Timing control |

Timing control function:setting range 0.0Sec~6500.0Sec |

|

|

Motor temperature overheat protection |

Need optional I/O extension card. The ACI terminal of VT300 supports both PT100 AND PT1000 motor temperature sensor. |

|

|

Speed deviation judgment |

Speed deviation judgment function to find positional risks in time |

|

|

Forced speed switchover |

Forced speed switchover, preventing elevator over travel top/bottom terminal |

|

|

Direct travel ride |

No-creeping running with the direct travel ride command |

|

|

Startup compensation |

Three startup torque compensation modes: analog, digital,no-load-cell |

|

|

I/O features |

Command source |

Operation panel control,Terminal control, Communication control (You can perform switchover between these sources in various ways.) |

|

Frequency source |

4 frequency sources: digital setting, multi-speed setting, analog voltage 1 setting, analog voltage 2 setting |

|

|

Assist frequency source |

10 assist frequency source |

|

|

Input terminal |

10 DI terminals, one for high-speed pulse input(also source PNP or NPN input) 2 AI terminal, one for voltage input, the other for voltage or current input |

|

|

Output terminal |

3 transistor output terminals 2 relay output terminal 1 AO terminal(0/4~20mA or 0/2~10V,used for frequency reference or output frequency output) |

|

|

Display and Operation |

LED display panel |

Display the parameters |

|

LCD panel & parameter replication |

LCD display panel optional* Parameter quick replication through LCD panel |

|

|

Key locking and function selection |

Lock the keys partially or completely and define the function range of certain keys so as to prevent malfunction |

|

|

Optional accessories |

LCD display panel, brake components, RS485 communication card, Profibus-DP communication card, CANlink communication card, CANopen communication card, MCTC-PG card(ABZ Incremental PG card +UVW incremental PG card+Resolver PG card 3in1) |

|

|

Environment |

Installation location |

Indoor,avoid direct sunlight,avoid dust cotton and metallic particles in the air, prevent from corrosive liquids and gases, oil mist and salt erosion,avoid rains and moisture. |

|

Altitude |

Below 1000m(de-rated 1% for each 100m high) |

|

|

Ambient temperature |

-10℃ to 40 ℃ (de-rated if the ambient temperature is above 40℃, maximum temperature 50℃) |

|

|

Humidity |

Maximum relative humidity 95%, non-condensing |

|

|

Vibration |

Less than 5.9m/s²(0.6g) |

|

|

Storage temperature |

-20℃ to 60℃ |

|

|

IP level |

IP20 |

|

|

Pollution level |

PD2 |

|

|

Power distribution system |

TN,TT |

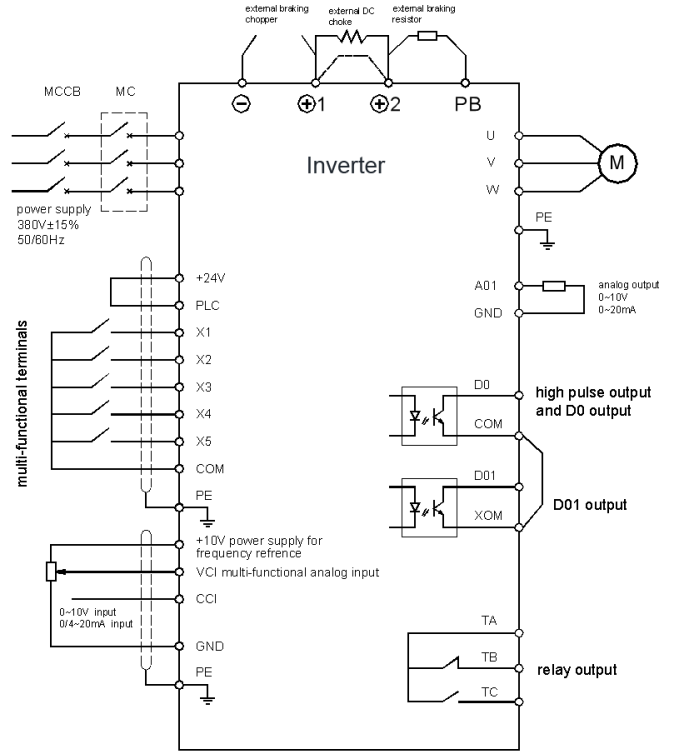

Wiring

|

Terminal name |

Terminal usages and description |

|

X1~X4 |

Switch input terminal, form bipolar coupling isolation input Input voltage range: 9~30V Input impedance: 2.4kΩ |

|

X5 |

High speed pulse or switch input, form bipolar coupling isolation input with PLC and COM. Pulse input frequency range: 0~100kHz Input voltage range: 9~30V

|

|

PLC |

User can access power to the external power directly (and COM), the +24V power supplied by this machine is also available, when VT300 series inverter leaves factory, the default is 24V and PLC short circuit. When using external power, please disconnect it from 24V. |

|

+24V |

Provide positive 24V power for this machine(current:150mA) |

|

COM |

The public side of 24V |

|

VCI |

Analog input, voltage range: -10~10V Input impedance: 22kΩ |

|

CCI |

Analog input, voltage(0~10V)/current(0~20mA)can be optional through J1 Input impedance: 10kΩ(voltage input)/500Ω(current input) |

|

+10V |

Provide positive 10V power for this machine. |

|

GND |

The reference zero potential for positive 10V (Note: GND and COM is isolated.) |

|

D0 |

High speed pulse or collector open circuit input terminal, its corresponding public terminal is COM Output frequency range: 0~100 kHz |

|

A01 |

Analog output terminal, among which A01 can select voltage or current output through jumper J2;. Output range: voltage (0~10V)/current(0~20mA) |

|

TA、TB、TC |

T relay output, TA public terminal, TB closed, TC open. Contact capacity: AC250V/3A,DC30V/1A |