VT80 series smart pump drive has an IP65 rated enclosure, providing excellent dustproof and waterproof performance. It is possible to be mounted on various types of pump motor junction boxes and compatible with a broad range of pressure sensors. Our smart pump drive is featured by high reliability, low noise level, stable performance as well as easy operation. The expansion RS485 interface can be configured independently from standard RS485 interface, preventing affect to each other. Coupled with independent RTC, this system is capable of accomplishing multi-pump control for both the main and auxiliary pumps

Power Range:

380V three-phase input: 0.75-18.5kW

Main features:

Control Mode: V/F control

Startup Torque: 1Hz 100%

Speed Adjustment range: 1:20

Overload: 20% rated current for 60s, 150% rated current for 1s

Multi-pump control, PID control, AVR function, wake-up function, flow control function,Stall control, Antifreeze function,

Water leak detection, Dry run protection,High & low pressure warning

Standard RS485 Modbus communication

Excellent dustproof and waterproof performance

Technical specifications:

|

Control Features |

Control mode |

V/F Control |

|

Start torque |

1Hz 100% |

|

|

Speed adjustment range |

1:20 |

|

|

Speed accuracy |

±1.0% |

|

|

Overload ability |

20% Rated current 60s, 150% rated current 1s |

|

|

V/F curve |

Straight line;quadratic curve |

|

|

Acceleration and Deceleration Time |

Acceleration and deceleration time range:0.1-800s |

|

|

Input and Output features |

Input Voltage Range |

220V/380V±15% Single Phase 220V/Three Phase 380V±15% |

|

Input Frequency Range |

50/60Hz±5% |

|

|

Output Voltage Range |

Three phase 0-rated input voltage |

|

|

Output Frequency Range |

0~50/60Hz |

|

|

Outer Port Features |

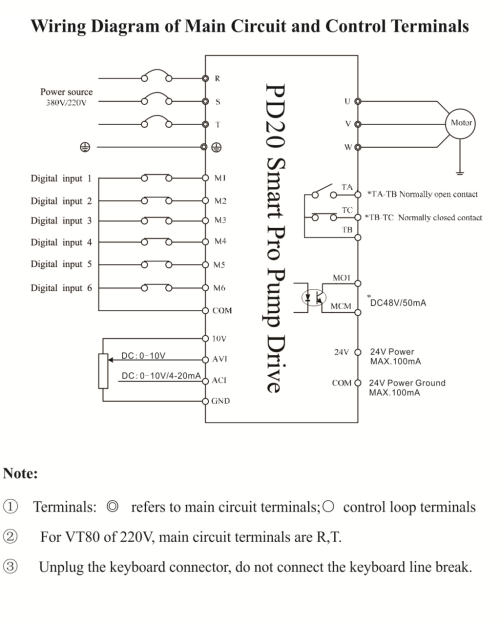

Programmable Digital Input |

2-way digital input terminals |

|

Communication Ports |

Standard equipped with 1-way shielded RS 485, can be extended with another way of RS 485 |

|

|

Programmable Analog Input |

2-way, can be set as current/voltage input by parameter settings; input voltage range: 0-10V; input current range: 0/4-20mA |

|

|

Analog Power Supply |

Dual power supply: 4-13V (adjustable)/24V |

|

|

Relay Output |

1-way output, programmable |

|

|

Open Collector Output |

1-way output, programmable |

|

|

Analog Output |

Reversed |

|

|

Basic Function Features

Basic Function Features |

Operation Command Route |

4 Routes: 1. Keypad control; 2. Digital input terminal control; 3. Communication control; 4. Water inlet pressure control |

|

Built-in Clock |

Built-in RTC for LCD keypad series |

|

|

PID Built-in PID |

Advanced PID calculation, convenient to realize close-loop control |

|

|

Host-auxiliary online system |

Can be extended to dual RS 485 communication; A driver can be set as the host in the system to control the work of other auxiliary drivers by communication (up to 5 auxiliary drivers). The host sends PID feedback to the auxiliary drivers and detects the state of them in real time. If there is an error, it will automatically skip this auxiliary driver, you can set a backup host. The host can communicate with the upper machine at the same time without being affected; The auxiliary drivers can also communicate with other devices at the same time. |

|

|

|

AVR Function |

Can automatically keep the output voltage stable when grid voltage fluctuates; This function is invalid when gird voltage decreases as factory setting. |

|

|

Stall Control |

Automatically limit output current and voltage during running, to prevent frequent overcurrent and overvoltage trips |

|

|

User Password Setting |

A 4-digit password can be set, which is a non-zero number; after setting, exit the password setting interface, it will take effect after 1 minute |

|

|

Parameter Lockup Function |

Define whether the parameters are locked under running or stop state to prevent misoperation |

|

Pump Control Functions |

Automatic Energy Saving Running |

Automatically lower output voltage at light load to achieve energy saving |

|

Automatically Startup when Powered on |

Optional: automatically startup when powered on, or startup delay |

|

|

Antifreeze Function |

Antifreeze operation selection, frequency, time, period |

|

|

Water Leak Detection |

Optimizing dormancy control by water leakage detection coefficient |

|

|

Water Supply Protection |

High Pressure Warning |

Detect the feedback pressure and protect the pipe network |

|

Low Pressure Warning |

Detect the feedback pressure and protect the pipe network & pump |

|

|

Dry Run Protection |

There are a variety of dry run protection detection methods (including sensorless methods). When the driver detects that the water pressure of the pipe network is lower than the dry run pressure, the system automatically stops working, and after a set time, it automatically restarts a specified number of times, if water pressure recovers to normal, the system enters the normal working state, otherwise, the system automatically shuts down to prevent the pump from idling in the absence of water, and extend the service life of the pump to the greatest extent. |

|

|

Application Environment |

Altitude |

Less than 1000m, derating above 1000m, 1% per 100m |

|

Environment Temperature |

-10 ℃ ~ ± 40 ℃, 40 ℃ -50 ℃ derating, 4% per 1 ℃ |

|

|

Vibration |

< 5.9/S2(0.6G) |

|

|

Storage Temperature |

-40℃~+70℃ |

|

|

Installation Environment |

Being dust and splash proof, the product is installed in a place not exposed to direct sunlight. |